An MES improves productivity and increases competitiveness

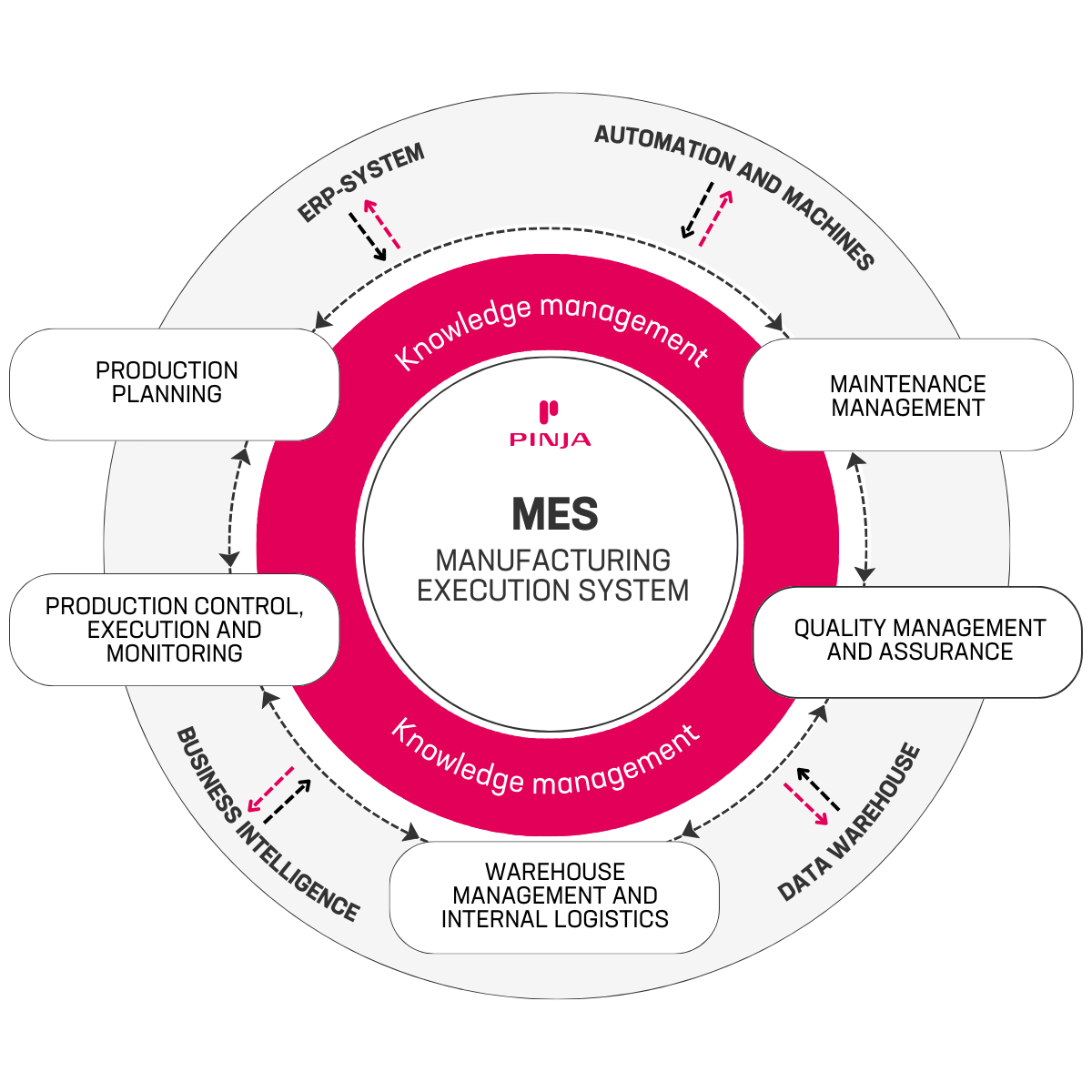

An MES (Manufacturing Execution System) is a tool for production management and development. It brings together the information flows about the order, product, materials, and processes needed to manage the internal production chain. The system brings together the entire company’s manufacturing operations, providing a transparent and visual view of production progress. The system ensures that all manufacturing work is completed and reported on time and according to plan.

Company objectives define the content of the MES solution

In 2000-2005, the American ISA (International Society of Automation) defined a standard called ISA-95, which defines the relationships and responsibilities between enterprise-level systems, factory floor operational systems, and automation in the manufacturing industry.

According to the standard, Manufacturing Operations Management (MOM) activities include those activities in the manufacturing production environment that coordinates personnel, equipment, material, and energy when raw materials are used to make parts and products. MOM functions generally cover production planning, scheduling, data collection, and reporting functionalities.

The demarcation and division of tasks between the MES and other systems used in production is not always clear. Therefore, the term MES is often inconsistently used for systems that include any MOM functions.

The standards roughly define the scope of MES, but there are many interpretations of what functionalities are included. When considering system acquisition, it is essential to remember that an MES is always a set that serves the needs of production, and the needs and expectations for the system vary greatly depending on the nature of the operation, the industry, or the objectives. It is important to identify the company’s needs and challenges in production, and try to solve them in the best possible way.

Is MES (Manufacutring Execution system) the same as ERP?

MES and ERP systems are an integral part of the selection of systems in the manufacturing industry. Enterprise resource planning (ERP) helps organizations manage and automate key business processes. The MES, on the other hand, focuses mainly on the management and control of production processes in the manufacturing industry. However, there is also a lot of overlap between the functions of the system.

Optimally, ERP and MES create an integrated ecosystem that provides a holistic view of a company’s operations, including sourcing, supply chain management, manufacturing logistics, and more. Understanding the roles and interplay of MES and ERP systems helps to perceive their characteristics, essential differences, and objectives.

In addition to providing a basis for production management and development, an efficient MES also supports the operator’s daily work. When management and operators can see the shift performance and what to do next, it helps them develop mutual interaction.

The benefits that an MES helps achieve:

Increased productivity

The MES helps companies digitize their operations, and adapt quickly and efficiently to changes in demand, opportunities, or requirements. The system allows you to optimize production processes and resources quickly and in real time.

Reduced lead time

The MES provides continuously updated information on the efficiency and performance of production lines. This helps identify bottlenecks in production and improve performance.

Improved security of supply

The MES improves the transparency and efficiency of the supply chain. This helps improve delivery times and ensure that deliveries are made according to agreed schedules.

Improved quality

The MES ensures that quality management measures, such as measurements and inspections, are carried out regularly and in a timely manner. This is particularly important in sectors where product traceability and compliance are controlled by legislation.

Reduced waste

The MES helps optimize stock levels of raw materials or finished products, among others. This reduces storage costs and minimizes waste.

Supporting decision-making with real-time data

The MES provides real-time data on the manufacturing process and its efficiency. This allows for quick decision making and changes in operational management when needed.

The information needed by production is usually obtained from various systems, machines, equipment, factory automation, and production workers. There can be several different systems used in production, such as PDM, SCM, and APS. All of these are often still interfacing with the enterprise ERP system. In addition, data collection systems are needed to gather information directly from machines and devices and the operators who use them.

To make production as smooth as possible, all systems should be simple and intuitive to use. Pinja’s MES solution makes it easier to manage everything by bringing together production control and the information needed for production in one system.

Who is an MES for?

The MES provides a tool for unifying digital, scattered information and helps ensure that employees have access to all the information they need. The MES is suitable for all manufacturing companies, but is especially efficient in solving challenges in companies where production data is scattered and poorly managed.

Our satisfied MES clients:

How should you go about acquiring an MES solution?

The idea behind the purchase of an MES may be, for example, the need to increase productivity, reduce lead times, improve quality, and enhance internal security of supply. In addition, there is often a need to facilitate the work of production workers, and to digitize scattered, manually collected data.

Before purchasing a system, it is important to review the current situation as thoroughly as possible, and in particular what you are trying to change. In addition to the data, it is also a good idea to review the current processes, and whether the current systems support the production process in the optimal way. Often, the aim of a system acquisition is to change a process, so one of the purposes of the project is to introduce new ways of working into everyday life.

We have written a guide to help you understand how to proceed with your MES acquisition. In this guide, we explain the concepts of MES in more detail, and the issues to be considered when purchasing an MES-level solution for the manufacturing industry.

Take a look at our additional professional materials:

Interested? Contact us!

The purchase of an MES is always a strategic decision that has an impact on the daily lives of many people working in a company. Not only does thorough familiarization make it easier to choose the right system solution for your company’s needs, it also speeds up the implementation of the software.