The operating environment of the manufacturing industry is evolving rapidly, and digitalization is changing the rules of the game. Maintaining and enhancing competitiveness requires companies to continuously adapt and embrace technological innovations.

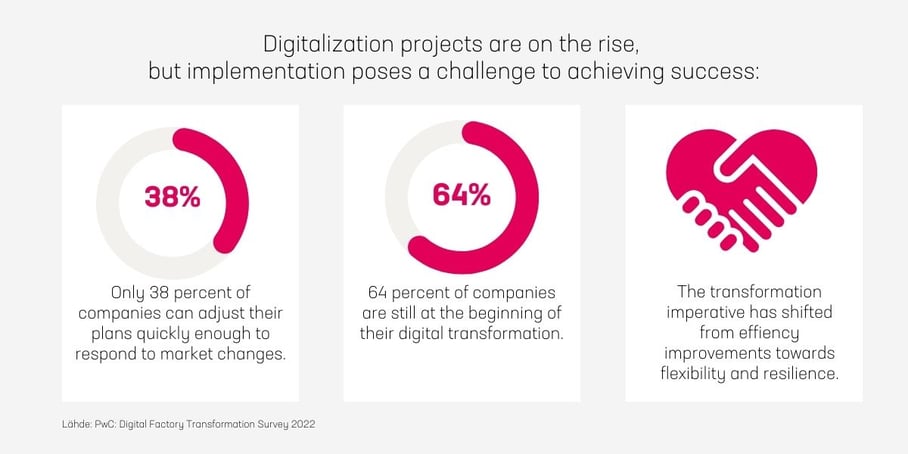

According to a report published by consulting firm PwC in 2022, the majority of companies (64%) are still in the early stages of their digital transformation and have not successfully scaled their digital initiatives. Only one in ten respondents reported that their company had completed its digital transformation program or was in its final stages.

While progress often occurs slowly, digitalization remains high on the agenda. Due to the scale of external disruptions in recent years, flexibility and transparency have become the key drivers of digital transformation.

MES System at the Heart of Change

Every path to change is unique, but at least one common factor is the expected and actual return on investment. Digitalization is the enabler of change, but there are several approaches to building or rebuilding the underlying IT architecture. One key "game changer" factor in this transformation may be the MES system.0

Benefits of MES system

Single interface

The information needed by production is usually obtained from various systems, machines, equipment, factory automation, and operators. Also, many systems have an interface solution for the company’s enterprise resource planning system.

To make production as smooth as possible, all systems should be simple and intuitive to use. The MES makes it easier to manage the whole by bringing together production control and the information needed for production in one place, which allows for the operational management of production through a single interface.

Digital reliable real-time data

To lead with information and increase productivity, you need reliable data. A well-suited MES system compiles information from production machinery, equipment, operators, and other systems and makes it available in real-time for all necessary personnel.

Data enriched by operator

Production work can vary widely and be much more diverse than it was just a few years ago. The added complexity means there are more things to remember, and if the information is stored on paper or in memory, the work cannot be managed.

It is good to remember that in addition to automatically compiled data, operators both enrich and report it. Therefore, the MES system brings insights into production management and development as well as the operator’s daily work. It guides the work of operators and provides them with a tool to report production issues directly into the system.

Order completion monitoring and information transparency

Is the order on schedule and if not, why? Are we ahead or behind in schedule? The MES system shows the production status and possible deviations at a glance for both operators and management.

Sharing clear visualizations of factual data increases communality and openness within the work community. Mutual interaction develops when both management and operators see how the shift has been performed and what should be done next.

Simple and timely quality management

The MES system not only provides information but actively guides the operator in timely production quality inspections, analyses, and monitoring. The analyses can be timed based on order completion or machine production amount. Reporting deviations makes it easier to respond to reclamations and trace orders and products.

Do you want to know more?

Download our free guide Procuring MES – What points to consider? for more information on the benefits of a MES system. In the guide, we go deeper into the concept of MES and explain what you need to consider when procuring a MES system for the manufacturing industry.

Read more:

Pinja MES: A scalable and modular production management system

Blog: What is OEE?

Blog: Why does digitalization of production require effective management?

Back to the Pinja Blog

Categories

- Career at Pinja (68)

- Manufacturing (48)

- Knowledge Management (45)

- Production Development (44)

- Software Partnership & Tools (42)

- Sustainability (37)

- Wood and Forestry (37)

- Bioenergy and Recycling (27)

- IT Support and Outsourcing (24)

- Ecommerce (23)

- Maintenance (22)

- Artificial Intelligence and Machine Learning (15)

- Public Services (9)

- Compliance (1)